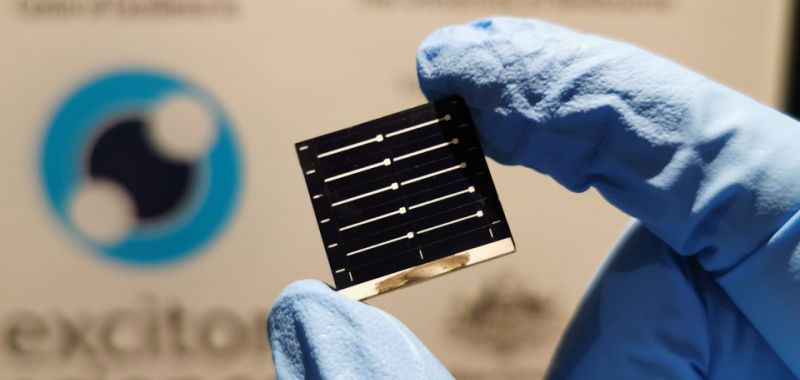

New protective layer boosts efficiency of thin film solar cells

Researchers in Australia and China have increased the power-conversion efficiency of thin film solar cells by 20% through the introduction of a temporary protective layer which improves crystallinity within the device.

Thin film solar cells made from copper, zinc, tin and sulfur-selenium (CTZSSe) are a promising next-generation photovoltaics technology.

They are made using earth-abundant materials and are more resistant to degradation in air and moisture than rival emerging technologies, such as perovskites.

CTZSSe cells are also solution processed (made using liquid) at lower temperatures than silicon, and do not contain toxic elements.

However, a key problem must be solved for this technology to become viable.

Heat treatment is required to promote grain growth of CTZSSe but this also triggers decomposition, leading to voids and defects forming in the resulting thin film, causing charge to be lost, and ultimately lowering device performance.

Previous attempts to resolve this issue involved thermally stable interlayers being introduced between the CZTSSe and back electrode molybdenum (Mo).

Unfortunately, this resulted in lower electrical conductivity and increased the complexity of the fabrication process.

Now, members of Exciton Science based at the University of Melbourne, and their collaborators at Central South University, have found a solution.

They used copper thiocyanate (CuSCN) as the intermediate layer, which suppresses the undesirable reaction between the selenium and molybdenum and the decomposition of CZTSSe.

The high-quality thin films synthesised via this mechanism demonstrated fewer recombination losses and enhanced charge carrier density.

And the test devices they produced have achieved power-conversion efficiencies of 11.1%, which is close to the world record of 13.0% for this type of solar cell.

First author Yixiong Ji, a PhD student at the University of Melbourne, said: “We are working on new inorganic solar cells made from materials that are cheap, stable and free from toxins.

“Together with our collaborators, led by Professor Fangyang Liu at Central South University, we have achieved an 11.1% power-conversion efficiency, which is close to the state-of-art for this kind of solar cell.

“We think a critical problem for this type of solar cell has been solved in this work.”

According to Yixiong, these type of thin film solar cells are also good candidates to stack on top of existing silicon cells, creating a more efficient and stable tandem device.

The results of this work have been published in the journal Advanced Functional Materials and are available here.